RAYNICE lamps comprehensive testing laboratory

Release time:2024-09-11

Raynice product comprehensive testing laboratory mainly tests the high temperature resistance, corrosion resistance, dust and water resistance of the appearance material of the lamp, collision resistance in different environments and transportation, lamp drive high and low pressure stability test, light source temperature test, etc

The main testing items are:

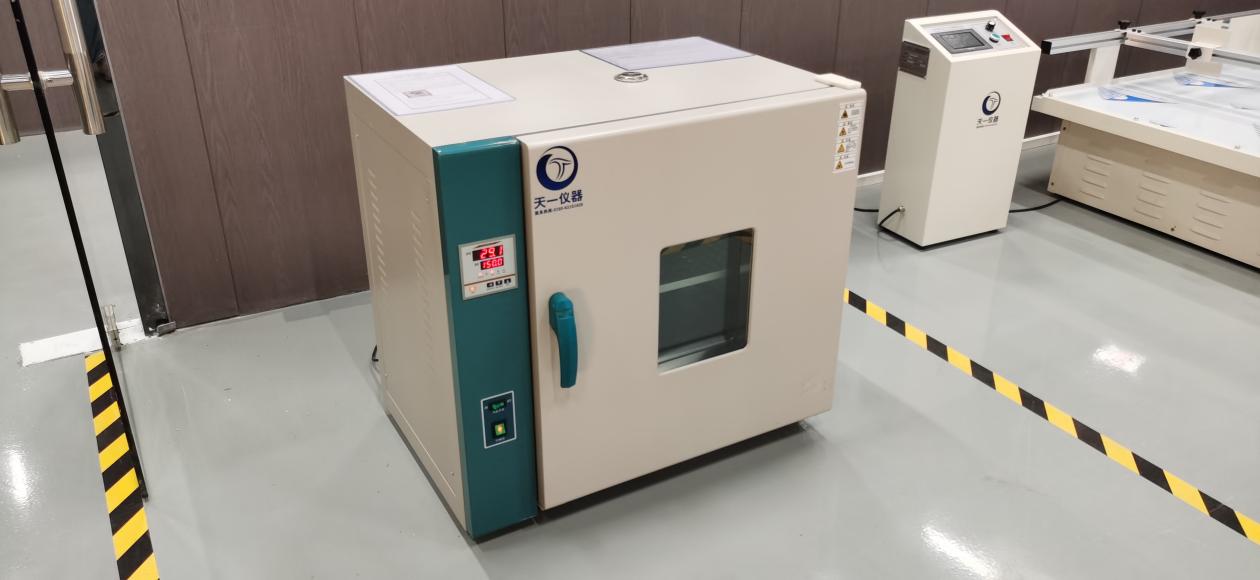

High temperature test (High temperature oven)

Used to test the reliability of the lamp parts in a high temperature environment for a long time, such as: Renis custom optical lenses, reflective cups and other plastic parts can pass 100~150 degrees of high temperature resistance test, in the lamp for a long time to use the light source to produce high temperature, the plastic parts inside the lamp is not easy to deformation, so as to ensure the light efficiency of the lamp and the service life of the lamp.

Mechanical Vibration Test (Intelligent simulated Motor Transport vibration table)

It is mainly to simulate the impact of the collision and extrusion of the product in the car compartment when it encounters different road conditions such as bumps, uphill, downhill, turning, etc., so as to further improve the product quality and packaging quality. The outer packaging of Renis uses 5 layers of thickened corrugated cardboard, and each inner packaging uses 3 layers of EVA cotton and the inner card design of the luminaire to achieve double protection for the luminaire, and no deformation and damage occurred in all the luminaires during the test.

Drop test (double arm drop tester)

It is mainly used to test whether the product packaging is affected by the drop impact at different heights during the actual transportation and loading and unloading process. The maximum height of the test is 2 meters, and the minimum height is 1 meter.

Rain test (rain test chamber)

Through 10 hours of environmental simulation, the product is tested in different environments of spraying, soaking and other tests to test the waterproof performance of the product. Ensure that every outdoor luminaire is IP65 protected.

Salt spray test (automatic intelligent salt spray testing machine)

It mainly uses the artificial simulated salt spray environmental conditions created by the salt spray test equipment to test the corrosion resistance of the product and its parts.

High and low temperature test (programmable high and low temperature test chamber)

It is mainly used to test the working state of the product at extreme ambient temperatures, such as the working state of the product at a low temperature of minus 20 degrees or a high temperature of 60 degrees.

Burn-in test (Drive burn-in cabinet)

The main test light source drive in the process of high and low pressure constantly changing, whether the drive can operate normally, usually in a constant temperature environment of 47℃ continuous power for more than 24 hours.

Temperature rise test (Temperature test cabinet)

The surface temperature of the light source and the radiator is detected at a constant temperature of 35℃ to obtain the best matching data between the light source and the radiator. Renis' downlight test points are controlled to a temperature of 75° and a luminous flux of around 87%.

2. Product optical testing laboratory

Raynice Optical Laboratory has always been at the forefront of the lighting industry, in order to ensure quality, and strive for accuracy and precision, with the size integrating ball, photometric distribution meter and other international advanced test equipment.

Photochromic integrated test system (Integrating sphere)

Used to measure the spectrum of different lamps, power, color temperature, color, coordinates, main wavelength, peak wavelength, color purity, color tolerance, color rendering index, color ratio, luminous flux, illuminance, brightness, radiation power, spectral reflectance, spectral transmittance, etc.

Lighting distribution Test System (Darkroom)

The luminosity distribution meter can test the photoelectric parameters of luminaires and light sources, such as total luminous flux and total efficiency, light intensity diagram and statistical table, central illumination, beam Angle, glare index, color spatial distribution, etc.

Related News

RAYNICE products material optical process

The color tolerance of RAYNICE light source is less than 2

2024-09-11

This article is not original, it is a translation. The original link can be found here [1]. Recently, I happened to be quite interested in lighting. When I was researching, I saw this article and thought it was pretty good. By the way, I will translate it.

2024-05-24

Light is actually an electromagnetic wave, light waves are only a small part of the entire electromagnetic spectrum, and the wavelength range of visible light is between 380-780nm. There is also invisible light. For example, ultraviolet and infrared. There are also electromagnetic waves, such as rays. Various waves, such as X-rays, account for the majority of electromagnetic waves.

2024-05-24